Increase Efficiency in Metal Processing with Nitrogen Generators

The metal processing industry is a broad field that includes many different operations such as cutting, welding, brazing, and heat treatment. During these processes, metals can be exposed to high temperatures, which can lead to oxidation, burr formation, and other issues. Nitrogen generators are highly effective tools used in the metal processing industry to prevent such problems and improve efficiency.

Benefits of Nitrogen Generators in Metal Processing:

1. Prevents Oxidation: Nitrogen is an inert gas and does not react with metals. Thanks to this property, it prevents metals from oxidizing during cutting and welding operations. Oxidation can cause metals to weaken and corrode. By using nitrogen, this problem can be prevented and the lifespan of metals can be extended.

2. Cleaner Cutting and Welding: Nitrogen reduces the smoke and dust generated during cutting and welding processes. This allows for cleaner and more precise operations. In addition, less smoke and dust create a healthier working environment.

3. Faster Processing Time: Nitrogen can be used to cool metals, allowing cutting and welding operations to be completed more quickly.

4. Lower Energy Consumption: Nitrogen consumes less energy compared to traditional cooling methods, helping to reduce production costs.

5. Safer Workplace: Nitrogen is a non-flammable gas. Thanks to this feature, it reduces the risk of fire and explosion in the workplace.

Applications of Nitrogen Generators:

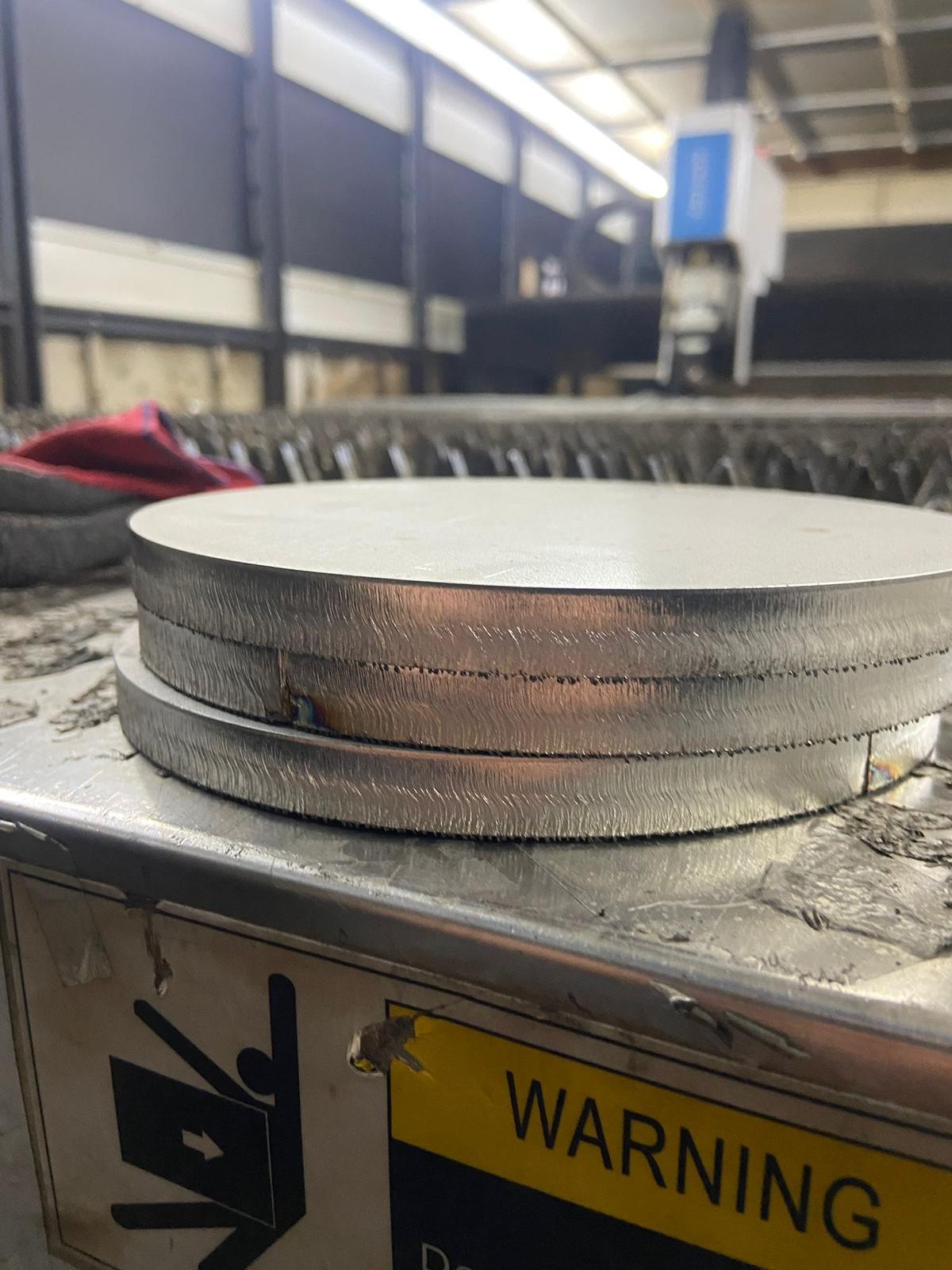

- Laser Cutting: In the laser cutting process, nitrogen prevents oxidation of metals and burrs.

- Plasma Cutting: Using nitrogen for plasma cutting results in a faster and cleaner cutting process.

- Welding: In the welding process, nitrogen prevents the oxidation of metals and helps create stronger weld seams.

- Heat Treatment: During heat treatment, nitrogen is used to cool metals and achieve the desired metallurgical properties.

Important Factors When Choosing a Nitrogen Generators:

- Capacity: The amount of nitrogen the generator can produce should match the needs of the metal processing facility.

- Purity: The purity level of the nitrogen used in metal processing should be high.

- Energy Efficiency: It is important that the generator is designed to provide energy savings.

- Ease of Use: The generator should be easy and practical to operate.

Nitrogen generators are highly effective tools used to increase efficiency and safety in the metal processing industry. By using nitrogen, metal processing facilities can reduce production costs, improve product quality, and ensure a safer working environment.