Dry Air Systems

Dry air systems started being used in cutting instead of only nitrogen and oxygen gases as laser cutting tables advanced. Cutting with dry air is much more cost-effective than using nitrogen and oxygen gases. There are technical points to consider when cutting with dry air. Dry air must meet specific standards and be free of oil and moisture. The air supplied to the laser from the final outlet of the dry air system must be free of oil and dust. The dew point should be measured, and a final check must be done before the air reaches the laser cutting machine.

In Forever Dry Air systems, high-pressure air produced according to ISO standards is used directly as cutting air. Thanks to the high-pressure air, the “old system of gas extraction with tubes” is eliminated. There are no additional transportation costs, tube transportation labor is eliminated, and the hazards posed by high-pressure tubes are also removed. The optional Dew Point Control Panel ensures oil-free and dry air is supplied to the laser head. The analyzers used in the system continuously measure and control the flow of dry, oil-free air. The system automatically shuts down if potential issues like oil contamination or condensation (water-moisture) occur in the pressurized air, stopping the air flow to the laser table and activating audible and visual warning systems to alert the operator. This prevents damage to the laser table.

100% Oil-Free

18 Barg “FOREVER” Dry Air Systems

FOREVER 18 Barg Dry Air Systems use oil-free booster compressors, unlike traditional 25-40 Barg oil-injected booster compressors. This prevents issues such as heated lens glass and mirror burn caused by oil, water, and particles that may be present in the compressed air from oil-injected boosters, thus avoiding malfunctions that are not covered by the warranty.

FOREVER 18 Barg Dry Air System Main Advantages

- 18 Barg dry and oil-free air

- Economical cutting capability

- – 40 °C dew point

- Max. 0.01 ppm particles

- Suitable for 24/7 operation.

- Easy to use

- Fully Equipped Safety System

- Fully automatic operating system

- Smooth, Fast, and Perfect Cutting

- 2–4 times faster cutting than oxygen cutting

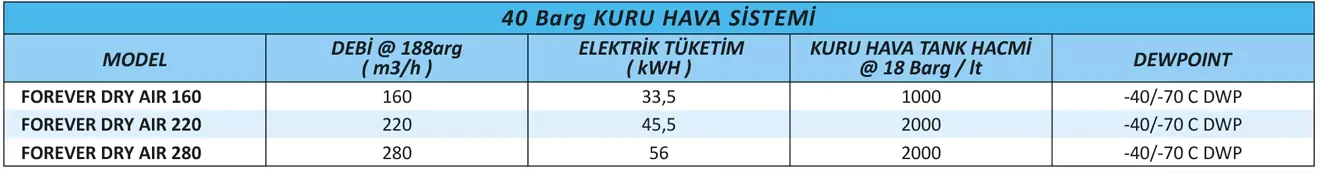

40 Barg “FOREVER” Dry Air Systems

Booster compressors used to compress air in the 7-10 bar pressure range can efficiently meet medium and high-pressure needs in the metal industry for laser cutting, laser and plasma cutting, and in the plastics industry for PET blowing and high-pressure gas injection. Our products are systems designed for 24-hour operation with high efficiency.

FOREVER 40 Barg Dry Air System Main Advantages;

- 40 Barg dry air

- Economical cutting capability

- – 40 °C dew point

- Max. 0.01 ppm particles

- Suitable for 24/7 operation.

- Easy to use

- Fully Equipped Safety System

- Fully automatic operating system

- Smooth, Fast, and Perfect Cutting

- 2–4 times faster cutting than oxygen cutting