Chemical Air Dryer

The air pressurized by the compressor may contain oil vapor and odor-causing particles that could damage our equipment or impact product quality. To prevent this, we recommend using Chemical Dryers with Integrated Carbon Towers.

Moisture is an undesirable element that harms the process and results in losses in compressed air systems. It also causes pipe corrosion, diameter reductions, and a chain of material issues that exacerbate each other

Contaminated air with impurities damages equipment when it contacts production process machinery. Compressed air is dried to prevent condensation and corrosion, which can disrupt production and contaminate products.

In sectors where the +3 °C dew point temperature from a refrigerated dryer is not enough, the dew point can be reduced to -70 °C using this method.

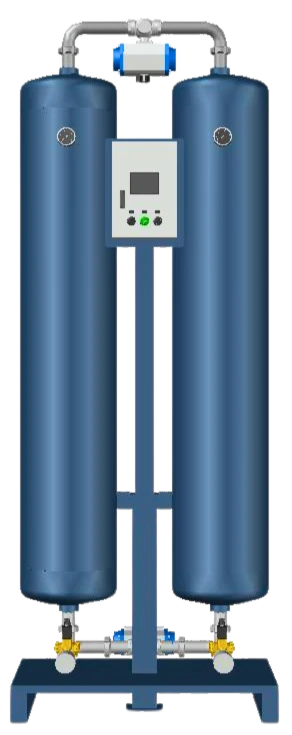

Forever Chemical Air Dryer systems, in simple terms, remove unwanted water from compressed air by physically separating it between tanks, providing the best protection for your system.

100% OIL-FREE

The two towers are filled with adsorbent material. H2O molecules attached to the surface of the adsorbent can easily detach due to molecular forces.

The first tower dries the humid air, while the second tower is refreshed with recirculated air flowing in the opposite direction. This is a physical reaction and can be repeated many times.

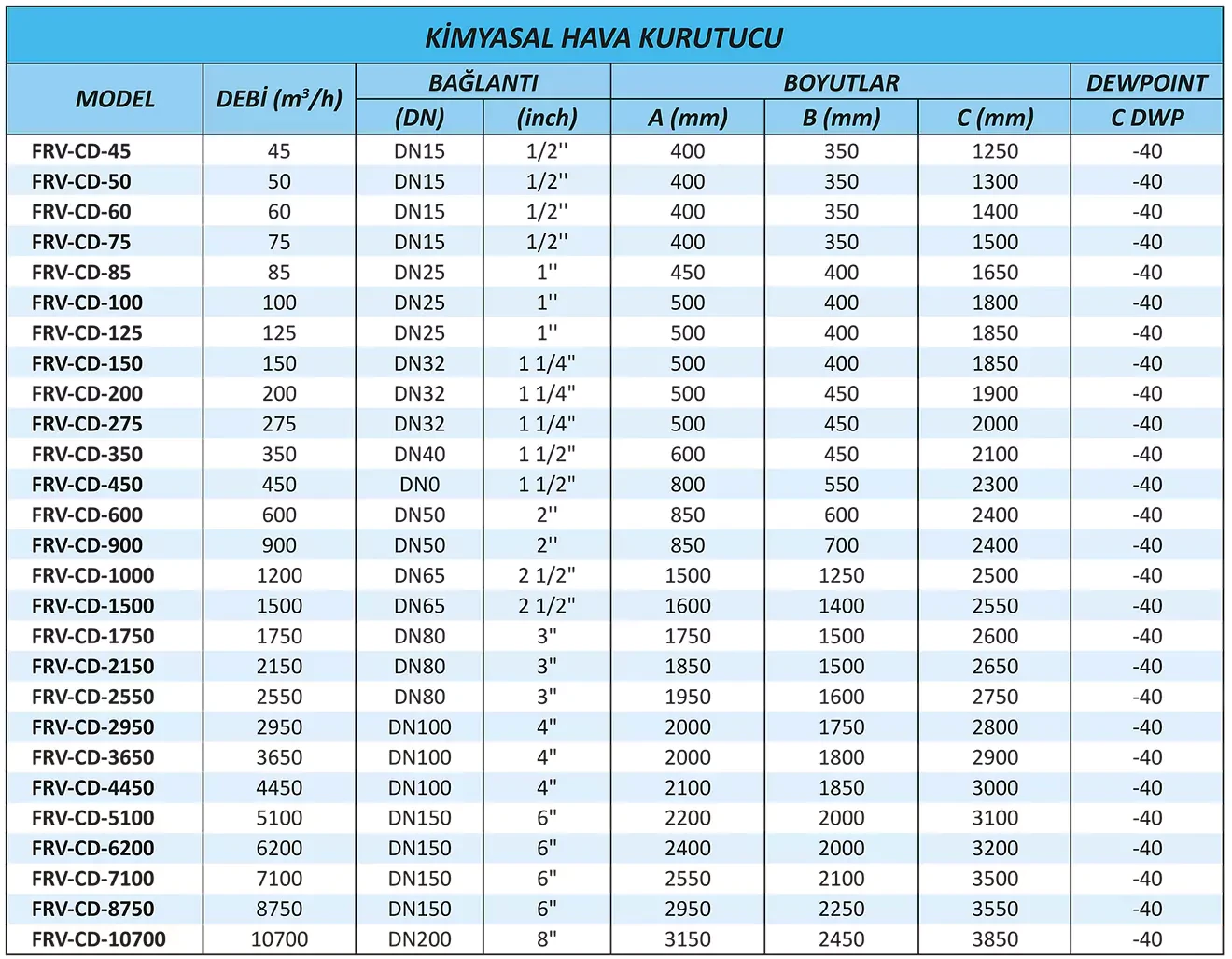

With its skilled team and 27 different model options, FOREVER GAS INDUSTRY is prepared to provide you with the most suitable solution.