Nitrogen Generator

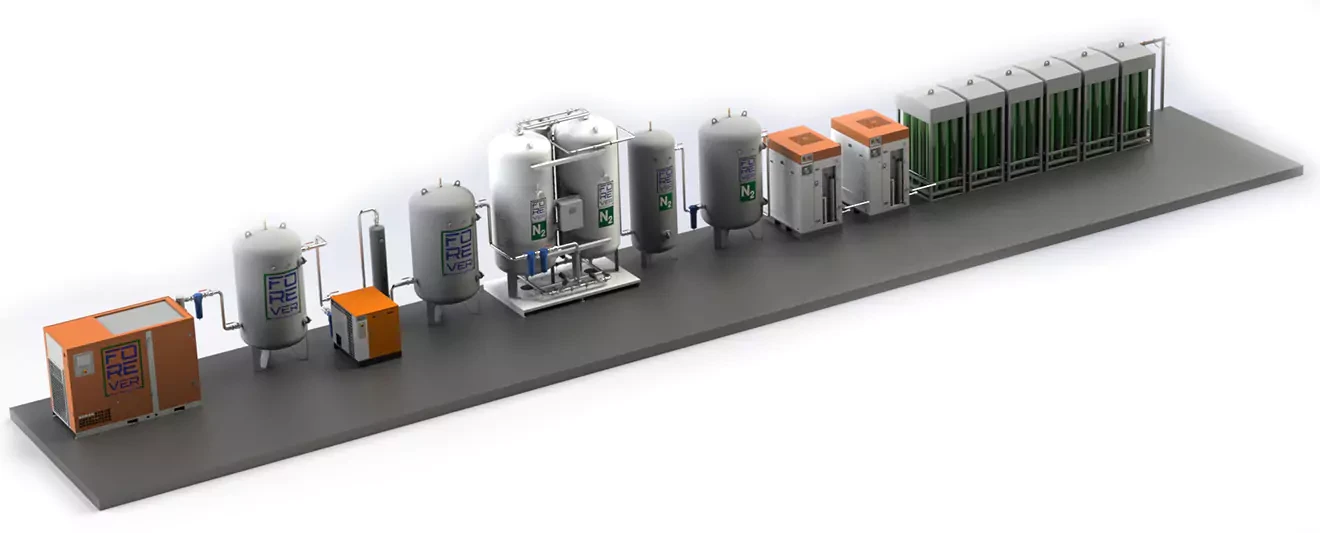

The nitrogen gas generator removes the need to rely on suppliers that produce cryogenic nitrogen. Our nitrogen generators, which use the PSA (Pressure Swing Adsorption) method, operate by physically separating nitrogen from oxygen in the atmosphere.

Forever nitrogen generator enables physical separation using high-quality CMS (Carbon Molecular Sieve). Unlike other nitrogen generator manufacturers, it provides valued customers the opportunity to produce nitrogen gas at a higher flow rate with less pressurized air.

As is well known, nitrogen gas is widely used in many sectors such as food, health, chemistry, mining, energy, electronics, laser cutting, and others. In some high-demand sectors, nitrogen gas supplied by cryogenic tanks is generally stored in high-pressure cylinders as a manifold.

99,9999% PURITY

As the distance to manufacturers grows, supply becomes more challenging and costs rise accordingly. Even when low pressure is required, manifolds compressed above 200 bar pose safety risks. Additionally, rental fees for tanks and manifolds also drive up operating costs.

The nitrogen generator provides the flexibility to produce as much nitrogen gas as needed. Especially for users who supply liquid with cryogenic tanks, they must deal with leaks that need to be vented into the atmosphere due to the pressure inside the tank, even when there is no usage.

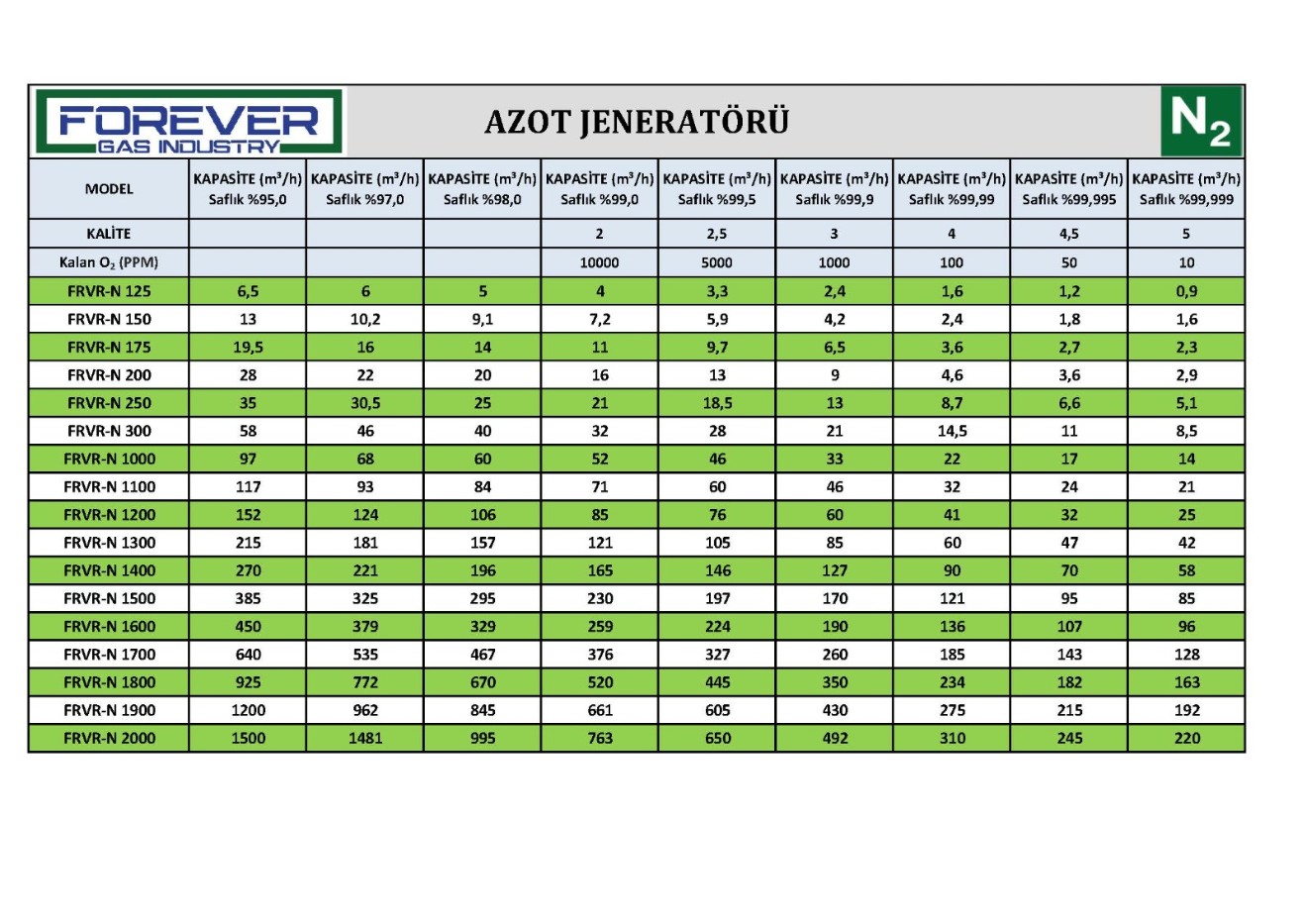

Forever nitrogen generators can produce nitrogen gas with up to 99.9999% purity for their customers, thanks to their high manufacturing and equipment quality. With our experienced and skilled staff and 17 different model options, FOREVER GAS is ready to provide you with the most suitable solution.

SIEMENS PLC, 7-inch Color Touch Screen, MODBUS/PROFIBUS/RMB

High-quality CMS with IP55 protection standard

Bürkert brand pneumatic valves and stainless steel transmission pipes.

Nitrogen gas is utilized in many industrial applications, such as laser cutting, paint shop processes, and food and hygiene operations. However, in practice, nitrogen is typically supplied and transported in filled cylinders. This method introduces supply issues and costs that vary depending on providers. Additionally, the delivery and pickup of cylinders by vehicle are not environmentally sustainable.

With its experienced staff and 17 different model options, FOREVER GAS INDUSTRY is prepared to provide you with the most suitable solution.

Main Features of FOREVER Nitrogen Generators

- You get the highest return on your investment with PSA technology.

- Create your own sustainable nitrogen gas.

- High purity is attained through carbon molecular technology.

- Nitrogen generators are built to run 24/7.

- Reduce external reliance with low maintenance costs.

- High-quality, durable zirconium dioxide oxygen sensor.

- Siemens PLC control system.

- 7-inch color touchscreen display.

- Modbus / Profibus / RMB communication.

- Bürkert brand pneumatic valves.

- Protection mode with dew point monitoring.

- IP55 standard protection.

- High-quality CMS.

- Ability to generate high nitrogen flow rates with minimal compressor power.

- Sustainable nitrogen energy production.

- Converting material losses into labor using PSA technology.

- Ability to attain high purity levels.

- Low maintenance costs.

- Savings on filling and transportation expenses.

- Nitrogen production with a capacity range of 0.5 to 2100 Nm³/h and a purity of 95% to 99.9999% (1 ppm).

Produce Your Own Nitrogen On-Site

With Forever Nitrogen Generators, you can easily produce nitrogen gas on your site anytime, in any quantity, and with the necessary purity. Along with offering chassis-mounted and space-saving solutions, we also provide container nitrogen generator systems that are installed, produce on-site, and are plug-and-play.

Main Advantages of FOREVER Nitrogen Generators: Fully automatic system:

- High-quality equipment.

- Exhaust and valve systems that require no maintenance or replacement.

- Profibus / Modbus data connection.

- LAN / Ethernet connections.

- Plug-and-play system.

- Mobile system mounted on chassis.

- Container mobile system.

- Filling the 200-bar manifold (tube bundles).

- Remote control functionality.