Carbon Tower Integrated Chemical Air Dryer

The compressed air may contain oil vapor and foul particles that could harm our equipment or lower production quality. To prevent this, we advise using Chemical Dryers with Integrated Carbon Towers.

Moisture is an unwanted feature that damages the process and causes losses in compressed air systems for the user. It also leads to pipe corrosion, diameter reduction, and a series of material problems that trigger each other.

Contaminated air with impurities damages equipment when it contacts production process machinery. Compressed air is dried to prevent condensation and corrosion, which can disrupt production and contaminate products.

In sectors where the +3 °C dew point temperature achieved with a refrigerated dryer is not enough, this method can lower the dew point temperature to -70 °C.

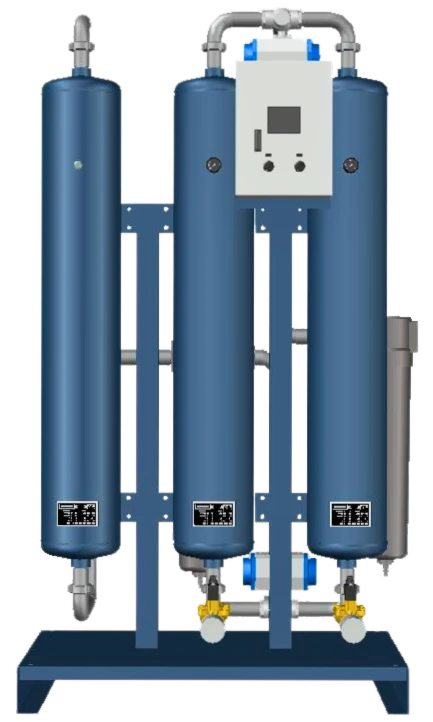

Forever Chemical Air Dryer systems, in simple terms, remove unwanted water from compressed air by physically separating it between tanks, effectively protecting your system.

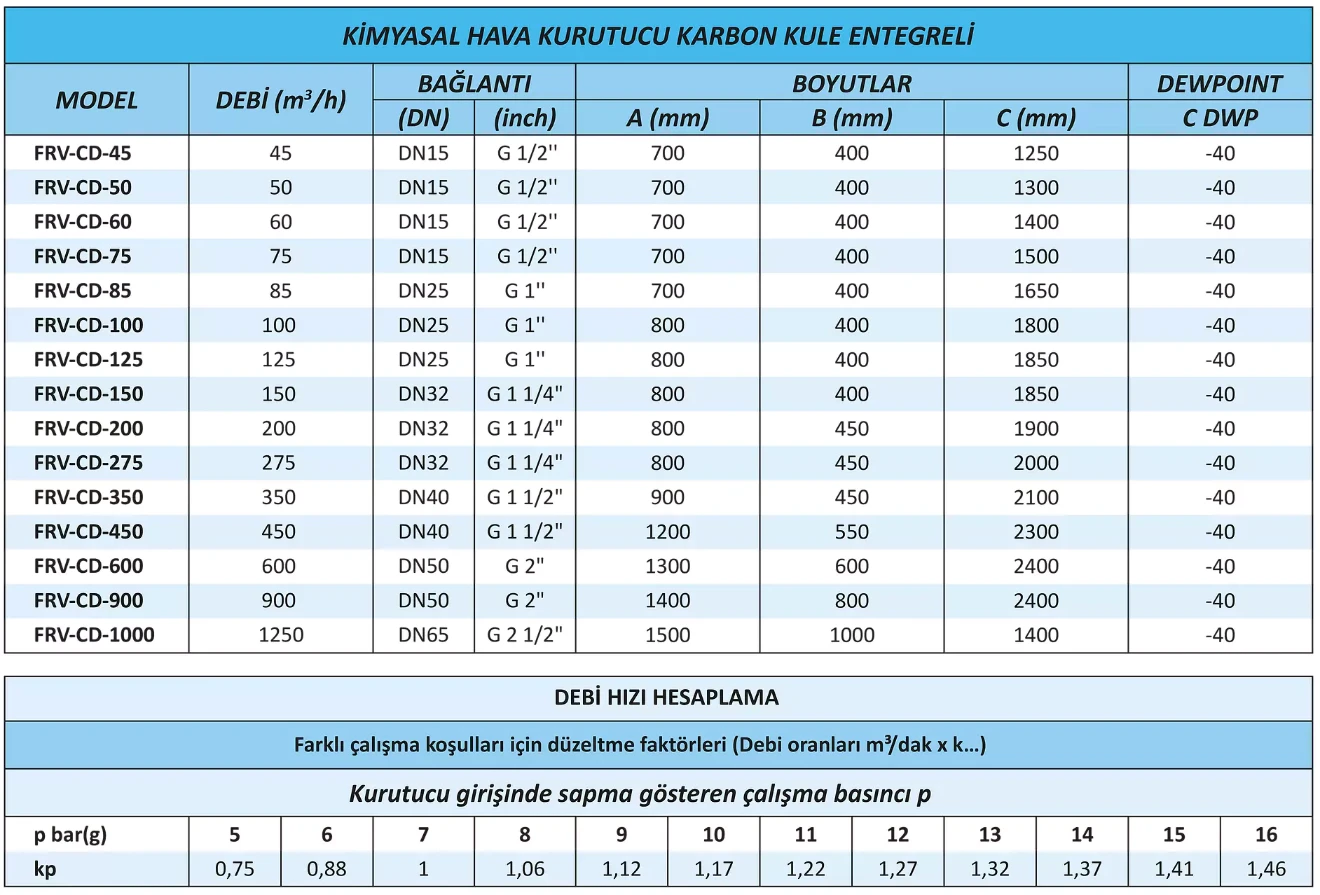

15 Different Model Options

Chemical Dryers with Integrated Carbon Towers

With its skilled staff and 15 diverse model options, FOREVER GAS INDUSTRY is prepared to provide you with the best solution. The first tower removes the humidity from the air, while the second tower is refreshed with recirculated air flowing in the opposite direction. This process is a physical reaction and can be repeated many times. Thanks to this system, which features an activated carbon tower, you can dry your compressed air to your desired dew point and produce clean, oil-free dry air.

Dry air for cost-effective cutting

All our products are manufactured according to industry standards. They all pass detailed tests in our factory.

Stop paying for gas cylinders

We focus on reducing environmental impacts by using eco-friendly production methods.

Lower service expenses

With our expert team, we deliver effective solutions while prioritizing customer satisfaction.

With its skilled staff and 15 diverse model options, FOREVER GAS INDUSTRY is prepared to provide you with the best solution.